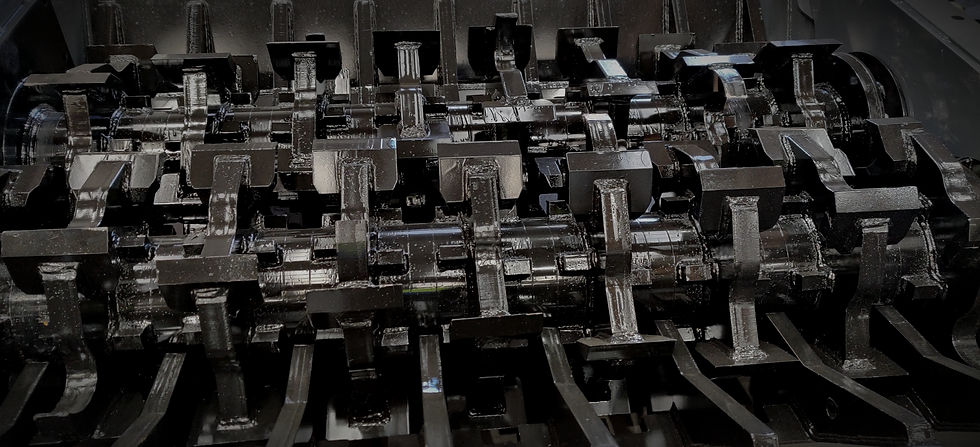

EDGE MC 1400 SEPARATOR

4 STREAM AIR SEPARATION + CLEAN SPLITS

Uses controlled airflow to separate material into up to four fractions in a single pass—light, mid, heavy, plus optional ferrous removal—making it ideal for cleaning compost, biomass, and C&D streams. Operators can dial in results via adjustable fan speed, feed belt speed, and drum positioning to suit changing material and purity targets.

The unit is available in track, semi-trailer, or static formats with diesel/hydraulic, genset, or direct-electric power options, and its enclosed design helps maintain airflow integrity while minimizing dust and spillage—great for sites with cleanliness or emissions constraints.

WEIGHT (TONNE)

16T (17.6UST)

TRANSPORT WIDTH

2.8M (9’)

TRANSPORT LENGTH

10.7M (35’)

TRANSPORT HEIGHT

WORKING WIDTH

WORKING LENGTH

WORKING HEIGHT

3.4M (11’2”)

6.9M (22’6”)

11.9M (38’11”)

3.4M (11’)

MC1400

COMPONENT OVERVIEW

.png)

.png)

• Weight: 16 t (≈17.6 US tons)

• Transport (W × L × H): 2.8 m × 10.7 m × 3.4 m (9' × 35' × 11'2")

• Working (W × L × H): 6.9 m × 11.9 m × 3.4 m (22'6" × 38'11" × 11')

• Typical Discharge Heights: Heavies ≈ 2.66 m, Lights ≈ 3.10 m (model-year dependent)

• Conveyors: Wide feed/discharge conveyors for even spread and zero-spillage design (enclosed)

• Controls: Adjustable fan speed, belt speed, drum position for material-specific tuning

GO ELECTRIC WITH EDGE

.png)

IMPROVED PRODUCTIVITY

More power, torque, and faster shaft speed deliver high production capacity.

ADVANCED CONTROLS

New control system maximizes torque for longer, tougher applications.

ENHANCED ACCESSIBILITY

Larger chassis, fold-down sides, and cartridge shaft system make the unit highly accessible.

HIGH TORQUE & SPEED

Torque boosted from 90k Nm to 120k Nm; speed range expanded to 7–38 RPM.

EASY MAINTENANCE

Fuel, AdBlue, filters, and gauges are all accessible from one point.

INTELLEGENT PROTECTION

Smart system monitors shaft pressure and blocks non-shreddables to prevent damage.

SEPARATOR APPLICATIONS

C&D WASTE

GREEN WASTE

MSW WASTE

TIRES

MATRESS

WHAT SETS THE MC1400 APART

One-pass, four-fraction windshifting.

4-STREAM SEPARATION

Light, mid, heavy + optional ferrous removal in a single pass to reduce rehandling.

EASY CONTROL ADJUST

Tune fan speed, feed belt speed, & drum position for clean splits across variable feeds.

ENCLOSED FLOW PATH

Encased design preserves airflow, limits dust, and cuts spillage for cleaner operation.

MULTI MODES

Chassis & power modes to track, trailer, or static w/ diesel/hydraulic, onboard, or direct electric drives.

.png)

A CLOSE COMPARISON OF THE EDGE MC1400

.png)

WHY PROTRACK?

01

EXCLUSIVE CANADIAN DEALER

Your trusted source for Terex Finlay, Edge Innovative & used equipment.

02

FULL ACCESS FINLAY LINEUP

Full line access to powerful Finlay Crushers, Screeners & more.

03

LOCAL EXPERTISE

Bringing years of equipment knowledge & responsive service.

04

FULL SERVICE SUPPORT

Include training, delivery, financing, serivcing, parts & more.

.png)

.png)

%20(4).png)